Your cart is currently empty.

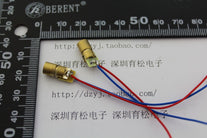

Module TCRT5000 infrared reflective proximity switch sensor module

Rs. 170.00

Availability: In Stock

SKU : CC1212125431

Quick OverView

Module TCRT5000 infrared reflective proximity switch sensor module

Qty: